Getting the Hobbit House Frame Materials (2)

STEP TWO: WOOD FOR THE HOUSE FRAME

Barry’s cousins, the Knowles, own a sawmill in nearby Pangatotara. But Lloyd and Diane, we discover, only have milled timber available, rather than whole poles. Lloyd suggests we speak to Ned, his elderly cousin, who has a eucalyptus plantation next door. A quick stroll in the grove reveals eucalptus of various sizes, many straight as an arrow, others with a ‘hobbity’ curve.

But will Ned sells them to us, and if so, at what price?

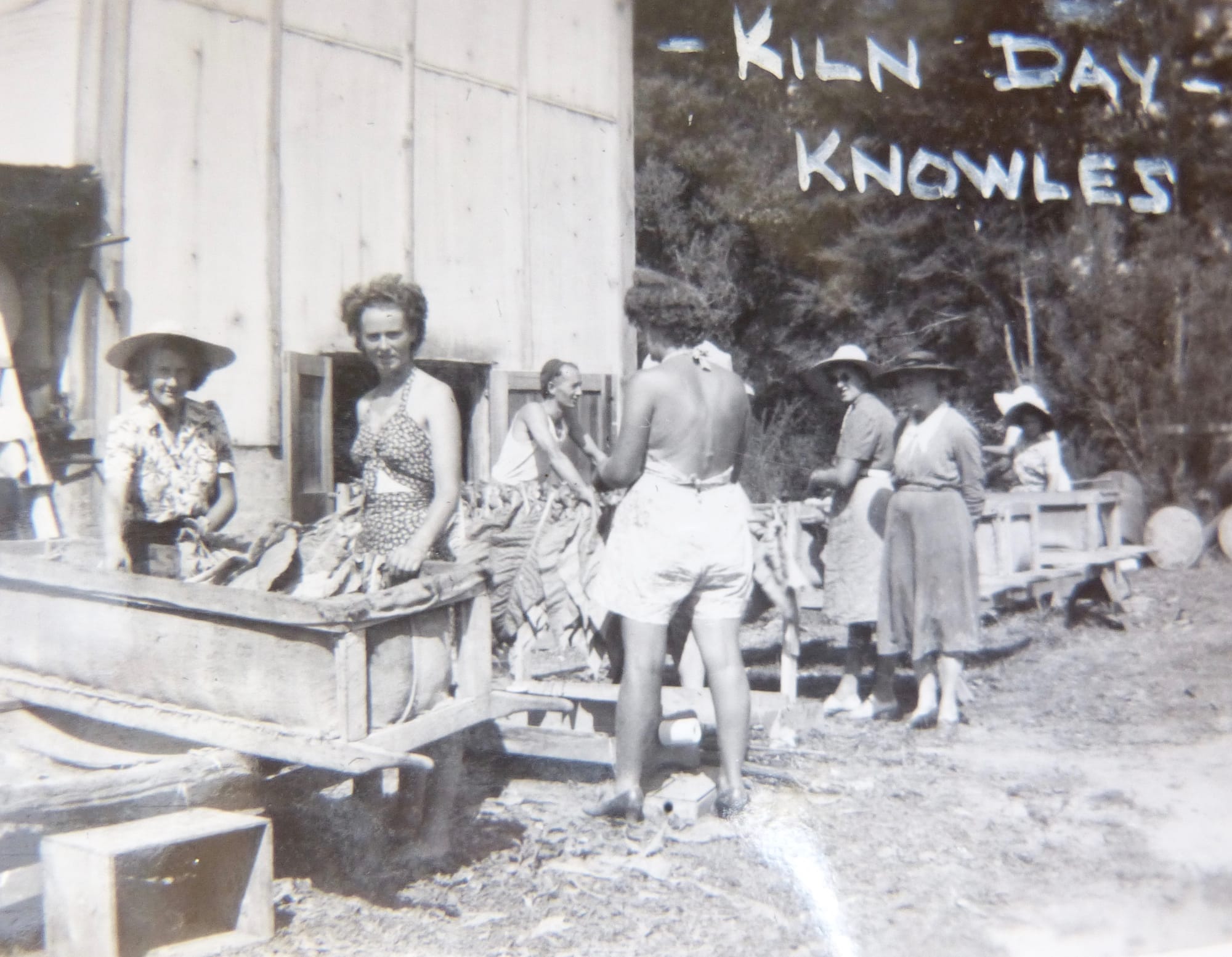

We drop by to see Ned, and explain who we are. He invites us to join him at his outdoor table for a cuppa (as they say here in New Zealand). We explain our purpose: obtaining eucalptus trees for our hobbit house frame. Ned’s mind wanders like a caterpillar onto other green topics. He details the historical tobacco growing of Pangatotara and the planting and harvesting and kiln drying of tobacco.

Ned describes the changing government attitudes toward the growing of tobacco and the payouts that encourage growers to other industry (in this case, forestry.). We gently steer the conversation back to our original topic. We estimate how many trees we will need for our project. Ned leads us inside and we tour his home. He shows us his wall collection of photographs from Norfolk Island and around the world. We ask Ned how much money he wants for a dozen or so eucalptus trees. He evades a direct answer but warns: “If you give me too much money, I’ll give some back.”

Trusting that we’ll have a square deal in the end, we return home for trailer, chain saw, ropes, and today’s lumber list. Sandra from Germany continues to assist us.

Barry fells trees. and cuts them to suitable lengths. Each tree yields a pole and a rafter, or more. Extra bits will become firewood.

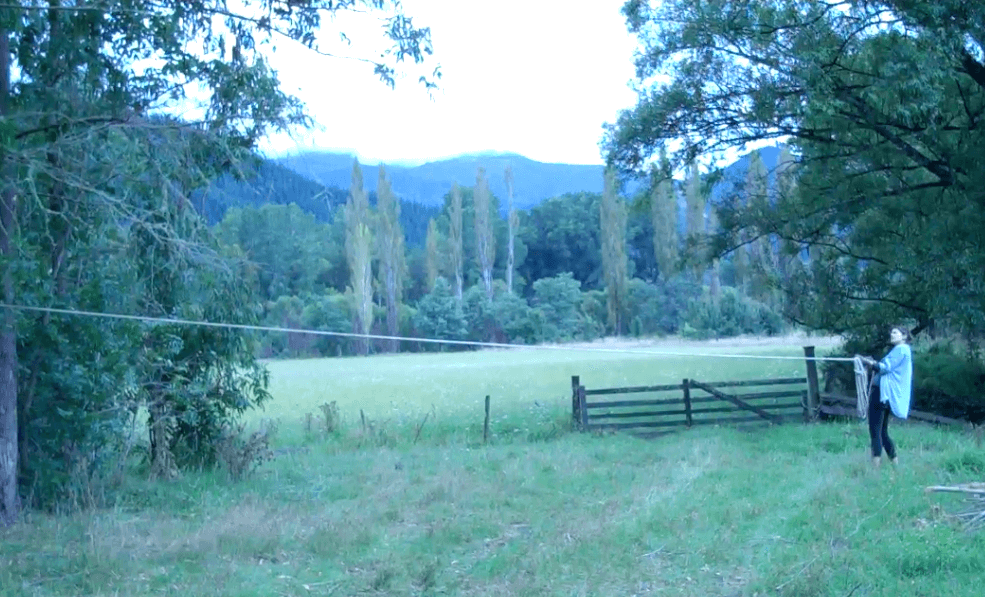

Numbers of sessions ensue to obtain our required supply of timber: a grand total of X posts X rafters, X purlins (connecting members). Our remaining task now, as required by Ned, is to pick up all the branches and leaves that we’ve stacked into a big pile, and haul them to a green waste dump. Before we can complete the task, a typhoon arrives! At home the paddocks flood. Waters recede at the Pease by morning. We attempt to head to town and discover blocked roads and destroyed bridges. We’re unable to drive in either direction!

When roads finally reopen, we visit neighbours and hear tales of woe. My friend Erena describes how two of her horses were stranded on a patch of ground huddled behind a tree in the middle of raging Shaggery creek (they thankfully survived); and how her entire ready-to-harvest hayfield washed away, complete with the underlying soil, leaving her with a sandy paddock,

In Pangatotara, the Knowles describe how raging river waters had carried all their many stacks of milled timber across the Motueka Highway and across their field. A row of trees prevented them from being swept out to sea. Our stacks of branches, however, did get a free ride. The spot where we’d been working was now meticulously clean!

And now, the financial reckoning. We needed to settle up with Ned for the wood for all the Hobbit House beams and rafters. I load my wallet with fifty and one hundred dollar bills. We try to estimate how much our supplies will cost. Five hundred dollars? Seven fifty? More, or less? We revisit Ned, who is in his kitchen. We greet him and state our purpose. He leads us into his computer room and sits us down and shows us one of his travelogue slide shows, a Norfolk Island holiday he took with his late wife. We return to the kitchen and have a cup of tea. I refocus our conversation to paying him and begin handing him fifties and hundreds. Ned deliberately hands bills back. He finally keeps one, a fifty. The grand total of fifty dollars, for all the ‘bones’ of our Hobbit House to be!

Sadly, Ned passed away at the end of 2019, never getting to see firsthand the product from his grove of trees. But his legacy lives on.

The next article will detail first steps in transforming the trees into usable materials.